|

THE FAN DOCTOR

|

|

|

Most industrial fans are very reliable, designed by knowledgeable

manufacturers for long life under a multitude of conditions. However, breakdowns

do happen. They can be caused by incorrect installation, lack of maintenance or

even improper fan selection. It can also be that years of strenuous service have

simply worn out the fan.

This page is presented as a guide, and not a technical service manual, more complex

causes and remedies are not included. Remember also that some ailments may have

more than one cause.

If you don't find the answer to your question here, please complete the help request

at the bottom of this page. Your request will be answered promptly by a qualified

Chicago Blower service technician.

|

|

|

|

| Vibration |

Noise | Overheated Bearings |

Poor Air Performance | Ask The Fan Doctor

|

|

|

|

|

Vibration

|

|

Cause

|

Remedy

|

|

The most common cause of vibration problems is out of

balance fan wheel or rotor.

|

Check the wheel for any dirt or foreign material, especially

hard-to-see places like the backside of the wheel and the underside of the blades.

|

|

|

|

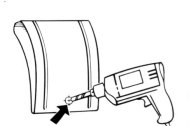

Airfoil blades are usually hollow. When exposed to rain

or excessive moisture, they can get water inside of them. Drilling one 3/16"

drain hole in the upper surface of each blade near the trailing edge should cure

the problem. Rebalancing is not usually necessary.

|

|

|

|

|

Inspect the wheel for corrosion or erosion. Usually wheel

erosion will occur at the leading edge of the blade. On a paddle wheel type fan

the outer blade tip may also be worn. An airfoil wheel exposed to sand or abrasive

dust can actually develop pin holes in the leading edge of the blades. Do all possible

to eliminate these damaging conditions and then rebalance the wheel. If the wheel

is seriously damaged, it will have to be replaced.

|

|

|

|

|

Improper or loose mounting.

|

Foundation bolts and bearing mounting bolts can loosen

themselves. Make sure they are tight.

|

|

|

|

|

Loose set screws that hold the wheel to the shaft.

|

Again, tighten the screws, but first be certain the wheel

hasn't shifted on the shaft or is rubbing on the inlet cone or drive side of the

housing.

|

|

|

|

|

Bent fan shaft.

|

First, check the shaft with a dial indicator. If bent,

it should be replaced as soon as possible to avoid replacing the entire fan.

|

|

|

|

|

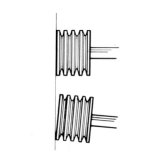

Misaligned V-belt drive, another very common problem on

belt driven fans.

|

Realign assembly so fan and motor shaft are parallel and

faces of sheaves (pulleys) are flush to a straight edge. We've found that a taut

string will work fine.

|

|

|

|

|

|

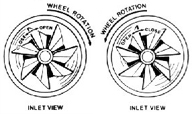

Fan wheel turbulence due to the rotor running backwards.

|

Since blade angles and shapes vary greatly, it is easy

to misread rotor direction. Check for correct wheel rotation, clockwise or counter

clockwise, as seen from the drive side. We illustrate the correct rotation for various

wheel types in CBC Course 100, page 4.

|

|

|

|

|

Air pulsation.

|

Fan may be operating in the stall area of its performance

curve. That means it is oversized for your particular system - refer to CBC

Course 100, paragraph 3.22 - or the system resistance is higher than intended.

You can lower the system resistance by cleaning the filters or opening the dampers.

|

|

|

|

|

Can't find the answer to your problem? Ask The

Fan Doctor.

|

|

|

|

|

Noise

|

|

Cause

|

Remedy

|

|

Foreign material in the fan housing.

|

This could be anything from a loosened bolt to somebody's

lunch bag. Inspect the wheel and inside of fan housing and clean thoroughly.

|

|

|

|

|

Squealing V-belts.

|

Belts are either loose or misaligned. If belts show wear,

you are better off to replace them now and avoid a future breakdown.

|

|

|

|

|

Worn ball or roller bearings. (Howling, screeching, or

clicking).

|

Change the bearings immediately before they cause additional

damage. Failing bearings tend to wear the shaft, so you want to be absolutely certain

the shaft is full size before installing these new bearings. "Mike" the

shaft both under the bearing and next to it and compare the two readings. If they

do not match, replace the shaft. New bearings installed on a worn shaft will not

last long.

|

|

|

|

|

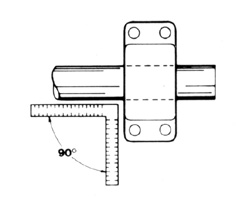

Bearing seal misaligned. (High pitch squeal).

|

Realign the face of the bearing so that it is perpendicular

to the shaft.

|

|

|

|

|

|

If the fan housing has a metal shaft seal it could be misaligned

and rubbing on the shaft.

|

Loosen seal plate bolts, re-center the seal on the fan

shaft and tighten the bolts. If the seal is fiberglass, cork or rubber, be sure

the metal backing plate does not touch the shaft.

|

|

|

|

|

Can't find the

answer to your problem? Ask

The Fan Doctor.

|

|

|

|

|

Overheated

Bearings

|

|

Ball or roller bearings tend to heat up when they have

been over greased and will cool down to their normal running level when the excess

grease oozes out. The normal operating temperature of a bearing may be well above

140°F which is hot to touch. Temperatures above this have to be read with instruments

and anything above 180°F should be questioned. If you place a drop of water on the

bearing and it sizzles, the bearing is in distress and should be changed before

it seizes and ruins the shaft.

|

|

|

|

|

Cause

|

Remedy

|

|

Bearing may be worn and failing.

|

Replace the bearings. Remember to also check the shaft.

(refer back to Noise section)

|

|

|

|

|

Improper grease.

|

Use a lithium base, high speed, channeling type grease.

Do not use high temperature or general purpose grease.

|

|

|

|

|

Over greasing.

|

If you allow the bearing to run for a few hours, it will

normally purge itself of the extra grease. You can simply remove excess grease from

split roller bearings by lifting the top half of the block for access.

|

|

|

|

|

Bearing exposed to "heat soak" from an oven or

dryer after shutdown.

|

"Heat soak" occurs when a fan is idle and its

shaft cooling wheel can no longer cool the inboard bearing. Heat from inside the

fan can actually cook the grease. A 15 minute fan run after the oven heat is turned

off will cool the fan shaft and protect the bearing.

|

|

|

|

|

Loose V-belts may cause belt slippage and friction heating

resulting in hot bearings, shafts or sheaves.

|

Tighten belt to proper tension. A good rule of thumb -

you should be able to depress the belt the same distance as the thickness of the

belt.

|

|

|

|

|

|

Excessive V-belt tension.

|

Belts may be too tight. Adjust to the correct tension.

|

|

|

|

|

Can't find the

answer to your problem? Ask

The Fan Doctor.

|

|

|

|

|

Poor Air

Performance

|

|

Cause

|

Remedy

|

|

Fan rotation incorrect.

|

Refer to Vibration section. An

easy way to change rotation on most 3-phase motors is to reverse any two motor leads.

|

|

|

|

|

Abrupt turn in the duct close to the fan discharge or air

pre-spin caused by ductwork elbows at the inlet.

|

Install turning vanes or elbow splitters in the duct. If

air performance is still inadequate, the discharge position may have to be changed.

|

|

|

|

|

If fan has an Inlet Volume Control (IVC), is it improperly

installed?

|

Be sure the IVC is installed with pre-spin of the air in

direction of wheel rotation when the IVC is partially closed.

|

|

|

|

|

|

Off-center wheel.

|

This can occur on double width, double inlet fans. Center

the fan between the inlet cones to avoid overloading one side of the wheel while

starving the other.

|

|

|

|

|

Fan horsepower unexpectedly low.

|

Correct one or more of the following conditions:

Air pre-spin into the fan inlet

Fan drive sheaves set for too low a fan speed

Resistance to airflow, such as caused by a closed damper, much higher than calculated

|

|

|

|

|

Fan horsepower unexpectedly high.

|

Be sure fan speed is not too high. Fan may be operating

without ductwork at low resistance so that too much air is flowing.

The fan may be handling ambient air when it was originally intended for hot, less

dense air.

Fan may be running backwards.

|

|

|

|

|

Can't find the

answer to your problem? Ask

The Fan Doctor.

|

|

|

|

|

Ask The Fan

Doctor

|

|

|

|

|

|

|

|